Heat & Cool

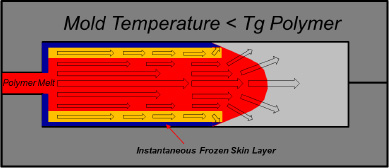

Rapid Isolation Cooling & Heating (Heat & Cool) is the process of RAPIDLY heating the surface of a steel injection mould tool to a temperature above the Glass Transition (Tg) temperature of an amorphous polymer or close to the Melting Point (Tm) of a semi-crystalline polymer, by flowing saturated high temperature steam through the mould tool’s cooling channels, PRIOR to injecting the polymer melt and then subsequently cooling the molten polymer, by flowing cold water through the same cooling channels, having first evacuated the steam using compressed air.

Benefits

- Super High Gloss finish (on polished tools)

- Elimination of all visible surface Weld, Meld and Flow lines

- No Glass Fibre visibility (resin rich surface)

- No silvering or splay marks (foamed resins)

- Better replication (transcription) of mould surface

- Lower filling pressures (up to 50%)

- Longer flow paths with lower wall section (Light Weighting)

- Less warpage and distortion (lower moulded in stresses)

- Less sinkage (better pressure transmission through melt)

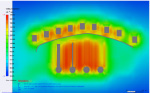

Moldex 3D thermal analysis of mould tool cooling channels

More than 8 years “hands on” process experience

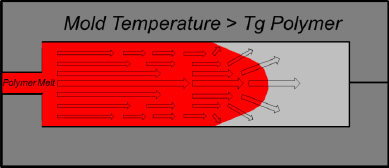

Standard Injection Moulding

Rapid Isolation Cooling & Heating